Recycling plastics, extracting oil - Our path to recycling

Turn your mixed plastics into oil - directly on site!

At AES, we focus on unused plastic resources because we transform them into high-quality oil. The oil can be processed further to re-create new materials. Our holistic approach includes complete oil management and offers you the opportunity to generate a real added value from unused resources.

Our highly customizable FLUKS systems are tailored precisely to your individual requirements. We support you step by step towards a more sustainable future.

Thanks to our fully automated system controls and our highly predictive maintenance system, you can sit back and relax. Our 24/7 maintenance service cuts downtime and repair costs to a minimum. Discover with us the possibilities of converting unused plastic waste into an economic value and benefit from our comprehensive range of services.

Cost-effective

With savings of up to 150,000 € per year and each reactor, this is a green investment which more than pays for itself.

Ecological

Up to 80 % less CO2 emissions compared to conventional thermal recycling

Efficiently

The system produces almost 90 % of the required electricity itself and transforms over 75 % of the used plastics into oil.

Compact

The AES FLUKS system fits inside a 20-foot container. An oil tank is installed next to it.

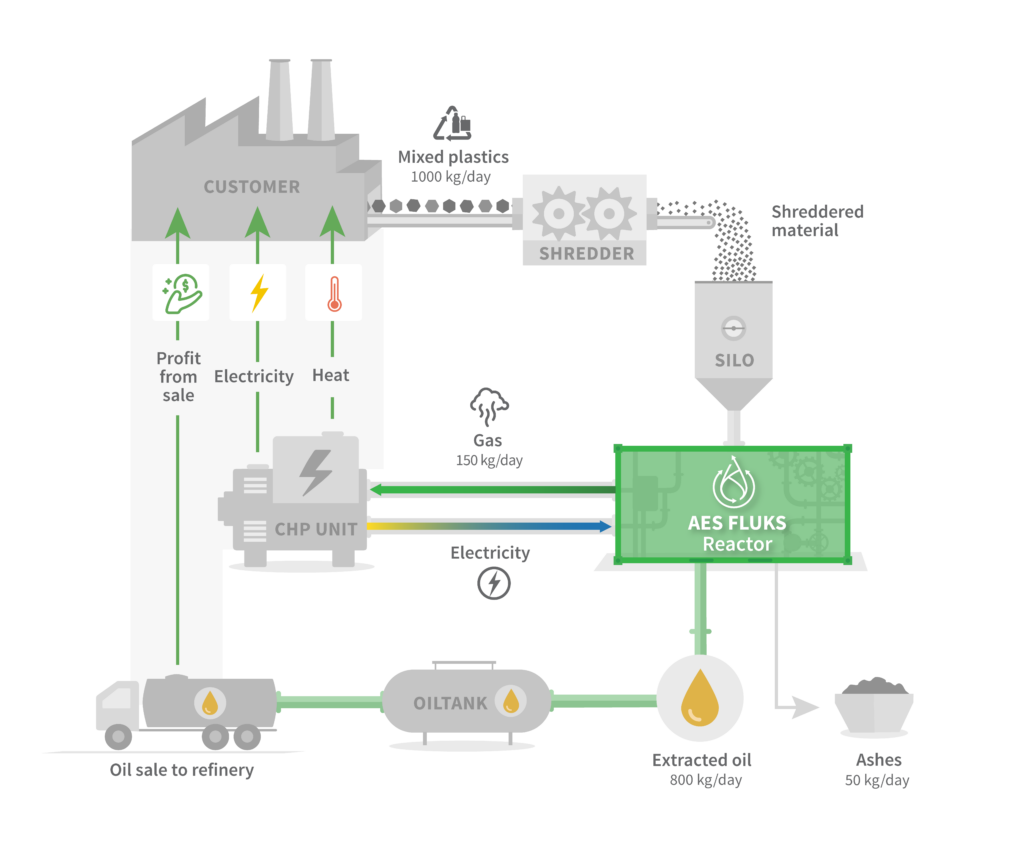

How AES technology works

The transformation of plastics into high-quality oil through AES technology

The AES FLUKS system series can process up to 1,000 kg/day of raw material. Thanks to the modular design, several modules can also be installed next to each other – allowing up to 5 tons per day to be processed.

All our systems are remotely monitored by our service team (24/7)

Our systems are designed for non-stop operation

The system is located on site at the customer's facility, so additional costs for logistics can be avoided

Project schedule

We support companies on their mission to recycle 100% of their mixed plastics. These include co-products from metal cutting or stamping or casting

In several steps, the AES team works together with you to work out an individual plan that is tailored to your needs on your way to a more sustainable future.

Based on our experience, we first analyze your material flow and reveal the full recycling and savings potential. Based on the results, we adapt the flexible and modular AES FLUKS system to the given requirements and create a product that fits your requirements perfectly.

"All-round service guaranteed by AES. Our service staff works for you 24/7."

Project schedule in months

- Taking sample material

- System test

-

Analysis of Oil, gas and ashes

- Refinery-Price

- Feedback

- Recycling capabilities

- System location

- Calculation of economic efficiency

- Long-term testing

- Master agreement

- Maximizing oil conversion

- Detail design

- Price calculation

- Authorizations (BimSchG)

- Installation and quality checks

- Initial start-up

- Training

-

System operation

-

Service and maintenance included

Recycling plastics, extracting oil - Our path to recycling

FAQ

We focus primarily on halogen-free, mixed plastic waste. E.g. PE, PP, PET, POM, ABS, SAN, PMMA, styrene, etc. We often process mixed or contaminated plastics. E.g. PE/PP/PS with 5 % contamination.

It takes approximately 2 years from the first material analysis (PS1) to the initial start-up of the AES FLUKS system(s).

Space is required for the reactor module (20-foot container), the oil tank (approx. 20-foot container) and the CHP unit (approx. 20-foot container). The shredder measures around 2m x 3m. There is a silo on top of the system’s container.

All you need is a power supply with 64 amps.

Each AES FLUKS 1000 reactor can process around 1 tonne of plastics per day and transform it into oil.

AES provides remote system monitoring as part of the 24/7 service package. No employee is required on site to monitor the system.

The AES FLUKS system reactor requires about 0.7 – 1 kWh per kg of material to be processed. The system produces almost 90 % of the electricity it uses on its own.

AES takes care of the entire oil logistics. Our customers receive a deposit on picking up the oil tank.

With savings of up to 150,000 € per year, this is a green investment that more than pays for itself.

The AES FLUKS system produces up to 75% less CO2 emissions compared to conventional thermal processing.